Device Description

The hemispherical design of the G7 acetabular shell provides fixation and stability with proven PPS® Porous Plasma Spray Coating1–7 or OsseoTi® Porous Structure. Multiple bearing options are also available, including E1® Antioxidant Infused Technology, ArComXL® Polyethylene, BIOLOX® delta** and Dual Mobility Cobalt Chrome (CoCr).

Note: The following surgical technique only applies to the G7 Dual Mobility System; please refer to the G7 Acetabular System surgical technique for traditional articulation instructions. The G7 Acetabular System utilizes a unique color coding system designed to offer an efficient operating experience. The provisional shells, liners and bearings match the labels and face plate impactors along with the color anodized on the rim and letter designation of the acetabular shell implant (Figure 1).

** Ceramic liners are not approved for sale in the US.

The G7 Acetabular System color and letter coding key is listed in Figure 2 along with a quick reference for Dual Mobility sizing and bearing thickness.

Note: Implant identification should be made using letter and size information. Color coding should be used only as a secondary reference. There may be slight variations in colors between components.

Preoperative Templating

Accurate preoperative planning and acetabular templating help determine the size, desired location and position of the acetabular shell and are an essential part of the surgical process. Templating is best performed with an A/P pelvis radiograph with the limb internally rotated approximately 15 degrees. This allows more accurate determination of femoral offset, radiographic leg length inequality, and referencing of contralateral hip, if required.

When examining the A/P radiograph, the shell should be positioned against, but not medial to, the radiographic teardrop at 40 degrees of inclination. Acetabular shell size is best determined on a crosstable lateral radiograph. If the patient’s anatomy is obscured, it may be helpful to check the acetabular component size on the contralateral hip radiograph, as well.

Make note of the shell size that fills the acetabular space appropriately and fits the anterior to posterior diameter of the native acetabulum, keeping in mind that final decision on shell size should be made during surgery when adequate visualization of the acetabulum is achieved.

Patient Positioning

The G7 Dual Mobility Acetabular System is designed to be used with all surgical approaches (Figure 3)

Acetabular Exposure

Prior to reaming, acetabular exposure should be adequate and the anterior, posterior and superior walls should be directly visible. The medial acetabular wall, which dictates the depth of the reaming, should be uncovered of floor osteophytes or pulvinar pad. Specialized acetabular retractors are available to help facilitate exposure for whichever approach is chosen.

Acetabular Reaming

Determine a starting reamer size from the preoperative template and from the measured diameter of the resected femoral head. This is typically 6–8 mm smaller than the femoral head diameter. Reamer handles are provided as straight or curved (offset). Use is dictated by surgeon preference, surgical exposure and patient body composition. During the reaming process, frequently determine the amount of anterior and posterior acetabular bone remaining to avoid reaming away the wall and compromising fixation.

Beginning with a small reamer, apply constant pressure first toward the medial wall, appropriately medializing the acetabulum for optimal hip biomechanics and the normal center of hip rotation. Gradually progress to larger reamers, while maintaining concentricity within the acetabular cavity until bleeding subchondral bone is exposed (Figure 4)

The preferred acetabular orientation is 40 degrees inclination and 20 degrees of anteversion, but final acetabular position depends on patient anatomy and may vary slightly with approach. Final orientation of the acetabular implant is also dictated by the amount of version of the femoral implant (i.e., greater anteversion of the acetabular component may be required in the case of a retroverted stem). Under-reaming of the acetabulum is dependent on bone quality and should be determined by the surgeon intraoperatively as soft bone will more readily accommodate a larger pressfit than harder, sclerotic bone. The following reaming recommendation may be used as an initial guideline:

Acetabular Reaming (cont.)

Once reaming is complete, use the provisional shells to confirm the position and accuracy of the reaming. Final shaping must be achieved using the hemispherical grater to ensure a congruent fit between the shell and the acetabulum.

Note: All G7 acetabular shells are measured over porous coating or structure. All acetabular shells, provisional shells and Biomet® acetabular reamers are marked true to size. All components are a full hemisphere and measure 180 degrees. The Dual Mobility liner offers 180 degrees of head coverage (Figure 5)

Optional Shell Trialing and Alignment

Once the desired ream has been achieved, select a provisional shell that is 1 mm smaller than the final implant. The provisional shell is marked with its true size and indicates the corresponding liner size both alphabetically and by color (Figure 6).

The shell gauge handle may be threaded to the acetabular shell provisional and used to gauge the size of the reamed acetabulum (Figure 6).

Note: Do not impact on the shell gauge handle

Optional Shell Trialing and Alignment (cont.)

Alternatively, utilize either the straight monoblock, curved or straight modular inserter handle. Place the provisional shell into the acetabulum at approximately 40 degrees of inclination and 20 degrees of anteversion.

When using the curved or straight modular handle, place the appropriate threaded shaft into the handle through the hole in the strike plate of the straight modular handle (Figures 7 and 8), or the hole at the distal tip of the curved inserter handle (Figure 9).

Optional Shell Trialing and Alignment (cont.)

Insert the ball hex driver into the hole in the strike plate of the straight handle or the hole at the distal tip of the curved handle and turn to advance the threaded shaft until the threads are exposed (Figures 10 and 11).

Line up the square tip of the insertion handle with the square at the apex of the shell trial. Turn the ball hex driver in a clockwise direction to advance the thread into the shell (Figures 10–12). Remove the ball hex driver from the handle. Ensure that the shell is securely fastened to the handle by lightly pulling on the provisional shell.

Approximate version can be obtained by using the transverse acetabular ligament or by referencing the opening of the acetabular component 90 degrees off of the sciatic notch. Alternatively, a positioning guide may be used.

If using the G7 Straight Monoblock Inserter Handle, assemble to the mating component by rotating clockwise and disassemble by rotating counterclockwise. Ensure the handle is fully threaded to the mating component prior to impaction.

Note: Levering on the inserter handle or impacting the handle on a location other than the strike plate to reposition the shell may damage the threads.

Optional Shell Trialing and Alignment (cont.)

Positioning Guides

The Lateral and Anterior Supine G7 positioning guides are designed to aid in proper insertion of the acetabular component.

Assemble the positioning guide on the back table before securing to the insertion handle. Connect the body of the positioning guide to the insertion handle by sliding the guide into the opening between the handle grip and shaft on the inserter handle. Slide the positioning guide into the flat opening on the guide body. When the guide is in place, tighten the positioning guide rod to secure the guide to the handle (Figure 13)

Lateral Guide

When positioning the acetabular shell, the lateral guide arms should be parallel to the table, aimed toward the patient’s ipsilateral shoulder (Figure 14).

For the right hip, use the reference arm of the “V” shaped guide labeled “RIGHT.” For the left hip, use the reference arm of the “V” shaped guide labeled “LEFT.” (Figure 14).

Optional Shell Trialing and Alignment (cont.)

Supine Guide

When positioning the acetabular shell, the anterior supine positioning guide arms should be parallel to the table, aligned with the patient’s spinal column (Figure 15).

For the right hip, use the reference arm of the “V” shaped guide labeled “RIGHT.” For the left hip, use the reference arm of the “V” shaped guide labeled “LEFT.” (Figure 15).

Note: The primary reference for acetabular shell position should be based on the patient’s anatomy. These instruments rely significantly on patient position and are designed to be used only as a secondary verification. If at any time there is concern about acetabular position, the orientation may be verified with intraoperative fluoroscopy or with intraoperative radiographs. A true A/P pelvis without rotation is best indicated when the tip of the coccyx lines up with the pubic symphysis and is within 1–2 cm of the symphysis.

Optional Shell Trialing and Alignment (cont.)

Optional Shell Trialing

Lightly impact the provisional shell and confirm complete seating through the cutouts on the provisional shell (Figure 16). Remove any soft tissue or osteophytes from the acetabular rim that overhang the edge of the provisional component to obtain proper seating. If the provisional shell is unstable, or if there are gaps between the provisional shell and the acetabulum, it may be necessary to increase the diameter of the final reamer. However, in some instances it may not be possible to increase the reamed diameter. If this is the case, then supplementary screw fixation may be necessary. Disconnect the inserter handle from the provisional shell.

Liner and Bearing Trialing with Provisional Shell

Following seating of the provisional shell, select the appropriate dual mobility provisional liner size, as indicated alphabetically and by color.

Insert the provisional liner into the shell by hand. Utilize a 3.5 mm hex screwdriver to tighten the screw in the dome of the provisional liner into the apical hole of the provisional shell (Figure 17).

Note: Do not overtighten the provisional liner.

Assemble the provisional head onto the trunnion. Select the appropriate dual mobility bearing provisional as indicated alphabetically and by color and assemble to the provisional head. Lateralization and leg length can be adjusted with neck length as determined by the surgeon.

Trial Reduction and Range of Motion

Ensure the provisional head is seated fully on the trunnion (Figure 18). When using the G7 self retaining provisional head in combination with a Type 1 reduced taper, a click is felt and/or heard when the provisional head is fully seated. Check for joint stability and range of motion, making any necessary adjustments to restore joint mechanics. Make certain that prominent impinging bone and/or osteophytes are removed from the periphery of the acetabulum to maximize range of motion and stability. Make note of all provisional components used and then remove all provisionals.

Acetabular Shell Insertion

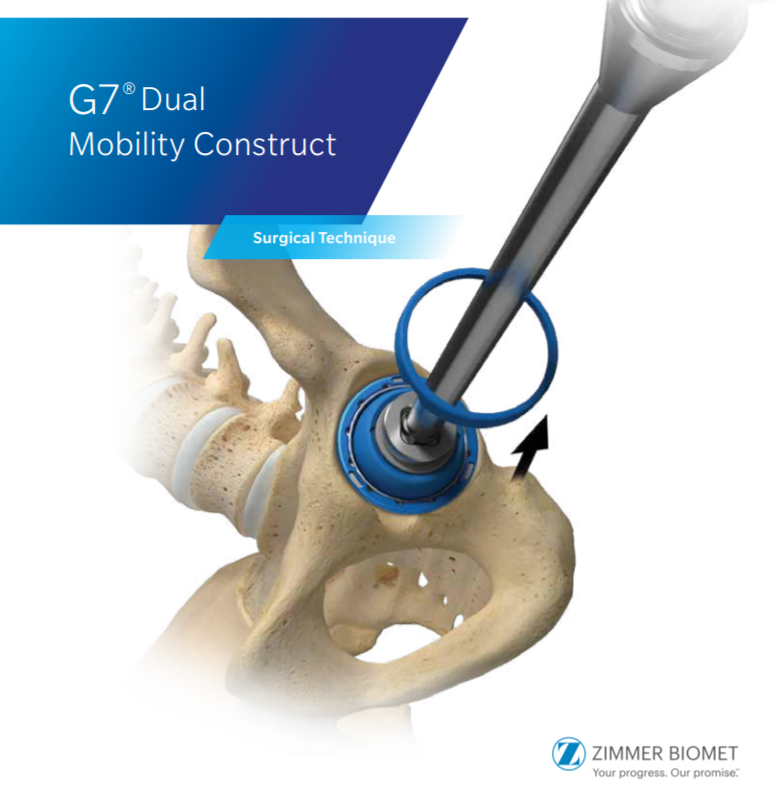

Similar to provisional shell insertion, the same curved or straight handle may be used for the final implant shell insertion (Figure 19).

Note: Limited hole shells are packaged with the screw holes pre-plugged. Should screw fixation be necessary, the screw hole covers should be removed using a 3.5 mm hex driver prior to shell insertion.

When using the curved or straight handle, place the appropriate threaded shaft (Figures 20 and 21) into the handle through the hole in the strike plate of the straight handle, or the hole at the distal tip of the curved handle inserter. Turn clockwise to advance the threads of the internal shaft through the tip of the impactor handle.

If using the G7 Straight Monoblock Inserter Handle, assemble to the mating component by rotating clockwise and disassemble by rotating counterclockwise. Ensure the G7 Monoblock Inserter Handle is fully threaded to the mating component prior to impaction.

Acetabular Shell Insertion (cont.)

Insert the ball hex driver into the hole in the strike plate of the straight handle or the hole at the distal tip of the curved handle and turn to advance the threaded shaft until the threads are exposed. Line up the square tip of the insertion handle with the square indentation on the inside of the G7 shell (Figure 22). Turn the ball hex driver in a clockwise direction to advance the thread into the shell (Figure 23).

Note: If the threads begin to loosen when impacting the modular inserter handle, utilize the ball hex driver to retighten and continue impaction.

Remove the ball hex driver from the handle.

Note: When the curved handle is used, the curve of the insertion handle should line up with the screw holes on the shell. Ensure the shell is securely fastened to the handle by lightly pulling on the shell

Acetabular Shell Insertion (cont.)

Alternatively, each inserter handle may also be utilized to insert the shell with a face plate impactor. Select the appropriately sized impactor plate that matches alphabetically and by color to the implant. Thread the impactor plate onto the insertion handle with the word “insert” facing the user (Figure 24).

The face plate impactor will align with any of the antirotation tabs on the face of the shell for impaction. These plates may be used with or without the optional quick connect bolt, which threads onto the face plate impactor (Figure 25). This bolt then snaps into the apical hole of the implant to retain the shell on the face impactor. Once inserted, the face plate is disengaged from the shell by lightly pulling backwards.

Acetabular Shell Insertion (cont.)

Alternatively, each inserter handle may also be utilized to insert the shell with a face plate impactor. Select the appropriately sized impactor plate that matches alphabetically and by color to the implant. Thread the impactor plate onto the insertion handle with the word “insert” facing the user (Figure 24).

The face plate impactor will align with any of the antirotation tabs on the face of the shell for impaction. These plates may be used with or without the optional quick connect bolt, which threads onto the face plate impactor (Figure 25). This bolt then snaps into the apical hole of the implant to retain the shell on the face impactor. Once inserted, the face plate is disengaged from the shell by lightly pulling backwards.

Acetabular Shell Insertion (cont.)

Use a mallet to impact the handle on the strike plate, driving the shell into the acetabulum. While impacting, note the position of the screw holes to obtain the optimal position for screw placement, typically in the posterior/superior quadrant of the acetabulum (Figure 26). There are 2 indents on the shell rim, to provide a secondary reference in identifying screw hole locations after the implant is inserted. Gently toggle the insertion handle to make certain the shell is stable. Once the implant is fully seated, reinsert the ball hex driver and turn in a counter-clockwise direction to release the threads from the shell. If using an impactor plate, pull back gently from the shell to disengage the plate.

Check through the apical hole to determine whether the shell is in full contact with the floor of the acetabulum. If not, the impactor handle may be reattached to the shell for further impaction, until the shell is fully seated. Failure to fully seat the shell into the acetabulum may compromise the quality of fixation. The force required to fully seat the implant depends on multiple factors including quality of bone, diameter of acetabulum and amount of underream.

Note: Ensure the G7 Straight Monoblock Inserter Handle is fully threaded to the mating component prior to impaction.

Note: Levering on the inserter handle or impacting the handle on a location other than the strike plate to reposition the shell may damage the threads.

Note: Consideration should be given to the location of screw holes prior to impaction, if screws will be used..

Optional use of Positioning Guide

The Lateral and Anterior Supine G7 positioning guides are designed to aid in proper insertion of the acetabular component. Utilizing the positioning guide as a reference, determine the correct position and alignment of the acetabular shell. See positioning guide section (Pages 9 and 10). In addition, approximate version can be obtained by using the transverse ligament or by referencing the opening of the acetabular component 90 degrees off of the sciatic notch. Position of the acetabular shell is crucial for optimizing wear, reducing impingement, reducing dislocation and reducing potential adverse outcomes.

Supplemental Screw Fixation

For cases where good bone stock is present and the shell is firmly seated within the acetabulum, the use of fixation screws is generally unnecessary. However, in cases where press-fit stability is in question, or where the bone quality is not optimal, supplementary screw fixation is advised.

Screw placement must be chosen carefully to avoid injury to neurovascular structures. Optimal position for screw placement is typically in the posterior/superior quadrant of the acetabulum (Figures 27 and 28). Care should also be exercised when supplementary screw fixation is required to avoid damaging or scratching the internal surfaces of the acetabular components.

Use of the gold screw drill guide is required for accurate screw placement. Consideration should be given to placement of a screw near the dome of the implant first to prevent possible shifting of the implant caused when placing peripheral screws

Note: Placement of screws outside of the “safe zone” may inadvertently injure neurovascular structures and should be utilized at the discretion of the operating surgeon. When using G7 Limited Hole shells, screws should never be placed in the anterior/medial area of the acetabulum. When using the G7 OsseoTi Multi Hole shell, extreme caution should be used if screw placement is required in the anterior/medial area of the acetabulum.

Supplemental Screw Fixation (cont.)

Use the gold drill guide to drill a pilot hole in the desired screw hole. Make certain the drill guide is fully seated and locked into position within the screw hole BEFORE the drill bit begins to engage bone (Figure 29). This will ensure the appropriate screw direction can be achieved. The G7 screw holes allow approximately 15 degrees of variability. Screws oriented outside this range may result in incomplete seating of the screws and prominent screw heads within the shell, which could impede insertion of the liner. When drilling into the posterior/superior quadrant, place a finger posteriorly into the sciatic notch to ensure the screw cannot penetrate too deeply.

Note: Levering on the drill bit during drilling may cause damage to the drill bit.

Note: Use only gold colored screws and the gold colored drill guide with G7 implants.

Note: Acetabular screws are to be fully seated to ensure stable fixation and to avoid interference with the G7 Dual Mobility CoCr liner.

The drill bits are available in variable lengths. However, 30 or 40 mm drill bits are most commonly utilized. The drill bit chosen should be dictated by surgeon choice and the projected length of the screws. To ensure proper seating of the G7 acetabular screw after drilling pilot holes, it is important to remove all bone debris from the screw hole prior to placing the screw. After measuring the depth of the hole with the depth gauge (Figure 30), select the 6.5 mm gold colored screw with the corresponding length and insert it into the hole with the 3.5 mm hex screwdriver and screw forceps (Figure 31). Place additional screws as needed. Screws should not be placed in the apical hole of the shell.

Optional Liner Trialing with Final Implant

Clean and dry the shell and clear all soft tissue from around its perimeter. If another trial reduction is desired, utilize the dual mobility provisional liner with the letter designation and color to match the rim of the shell. Insert the dual mobility provisional liner into the shell by hand. Utilizing a 3.5 mm hex screwdriver, tighten the screw in the dome of the dual mobility provisional liner into the apical hole of the final implant (Figure 32).

Note: Do not overtighten the provisional liner.

Assemble the provisional head onto the trunnion and ensure it is fully seated. Select the appropriate dual mobility bearing provisional as indicated alphabetically and by color and assemble to the provisional head (Figure 33). After appropriate provisionals have been selected, remove all provisional components.

CoCr Liner Insertion

The definitive dual mobility CoCr liner implant may now be introduced. Ensure that the interior of the shell and all tapers are dry and free of debris.

Select the appropriate hard bearing inserter ring, as indicated alphabetically and by color. The inserter ring is designed to properly align the taper interface for seating of the metal liner and its color will match the rim of the acetabular shell. Press the hard bearing inserter ring onto the face of the definitive liner implant (Figure 34). Visually verify the ring is fully seated against the face of the liner

Utilizing the straight insertion handle with a suction cup attached or the bent suction cup handle, gently seat the liner into the taper (Figure 35). Secure the impactor adapter to the impaction handle with clockwise turns (Figure 36a). Select the appropriate dual mobility provisional bearing based on size and color. Snap the provisional bearing to the impaction handle assembly (Figure 36b). Ensure the hard bearing inserter ring evenly contacts the face of the shell, prior to impaction (Figure 37).

Note: Apical plug cannot be utilized with the dual mobility CoCr liner.

Impact the definitive liner with several moderate mallet strikes. During impaction, the hard bearing inserter ring will disengage from the definitive liner and should be removed (Figure 38). When properly seated, the liner will sit flush with, the face of the shell (Figure 39).

Note: The definitive liner must be seated with impaction force. Pushing the liner into the shell by hand may result in malalignment. Failure to follow these instructions may result in damaged liners.

Note: The hard bearing inserter ring is for aligning the dual mobility CoCr liner to the acetabular shell only. The inserter ring does not confirm that the CoCr liner is fully seated and is not intended to protect the taper from damage.

Important: Care should be taken not to scratch the taper surface of the dual mobility CoCr liner or the shell, as damage may compromise locking mechanism performance.

CoCr Liner Removal

Should it be necessary to remove the dual mobility CoCr liner, the insertion/extractor faceplates can be used. Select the appropriate faceplate that matches the letter and color of the implant. Turn the insertion faceplate upside down so that the word “extract” is facing you and attach it to the impactor handle. Line the tabs up to the three recessed areas on the face of the shell (Figure 40a). Hit the impactor handle with the mallet several times to cause vibration and loosen the liner. Use the suction cup to grasp the liner and remove from the shell.

Alternative removal method: The G7 Tamp instrument is also available for liner removal. Line the tamp up to one of the three recessed areas on the face of the shell (Figure 40b). Hit the impactor area with the mallet several times to cause vibration and loosen the liner. It may be necessary to do this in multiple locations on the face of the shell. Use the suction cup to grasp the liner and remove it from the shell.

Note: The G7 Tamp should only be used on a well fixed shell or a shell with acetabular screws.

Note: Visual inspection of the shell taper surface should be done prior to placing another CoCr liner into the shell. Surface damage may compromise locking mechanism performance

Assembly of Dual Mobility Bearing and Femoral Head

Based on bearing size, select the appropriately sized femoral head referenced in the chart below:

Note: It is not recommended to utilize skirted heads.

Completely unscrew (open) the Head Press. Slide the baseplate onto the forked end of the press (Figure 41). Tighten the baseplate to the press with the knob (Figure 42).

Assembly of Dual Mobility Bearing and Femoral Head (cont.)

Place the femoral head on the black lug of the baseplate (Figure 43). Position and hold the polyethylene bearing above the femoral head. Rotate the press handle clockwise until the head is forced into the polyethylene bearing (Figure 44) and a distinctive “pop” is heard.

Note: If using a BIOLOX delta Option ceramic head, insert the appropriate taper sleeve prior to placing the head on the black lug.

Open the press by rotating the handle counterclockwise. Check that the femoral head rotates freely within the polyethylene bearing. If it does not rotate freely, the femoral head is not properly engaged. In this case, place the construct back on the bearing press and repeat the compression steps.

Bearing Impaction

With the definitive acetabular liner in place, and upon completion of femoral implantation and trial reduction, the dual mobility construct can be implanted. After fully seating the femoral component, position the assembled dual mobility bearing onto a dry and clean trunnion. Fully seat the head and bearing construct by means of firm axial impaction utilizing the plastic construct impactor adaptor tip assembled to a straight G7 insertion handle or the blue Active Articulation™ head impactor (Figures 45a and 45b).

Note: Using a non-compatible bearing impactor could damage the bearing. +

Final Reduction

Once all final implants have been placed, perform the final reduction of the hip. Check for joint stability and range of motion, making any necessary

Bearing Construct Removal

In the event the head and bearing need to be removed from the femoral stem, align the tip of the offset punch on the back side of the femoral head and drive the head off the stem with a mallet (Figure 47)

It is recommended that new heads be used anytime parts are replaced, as unseen damage to the taper junction or head tolerances can negatively affect the performance of the implant. Always inspect the stem trunnion prior to continued use.

Straight Inserter Handle Disassembly

To disassemble for cleaning, place a 3.5 mm hex screwdriver in the tip of the threaded shaft. Turn the screwdriver clockwise while pushing lightly to disengage the threaded shaft from the handle (Figure 48)

Curved Inserter Handle Disassembly

To disassemble for cleaning, place a 3.5 mm hex screwdriver in the tip of the threaded insert. Turn the screwdriver clockwise while pushing lightly to disengage the insert (Figure 49).

Implants

Note: DM is compatible with all G7 shells.

*3 or 4 hole pattern dependent on shell diamete

Instruments

The components are intended for use with either primary or revision hip arthroplasties. In revision arthroplasties, all devices associated with the wear couple must be removed and replaced.

INDICATIONS

- Non-inflammatory degenerative joint disease, including osteoarthritis and avascular necrosis.

- Rheumatoid arthritis.

- Correction of functional deformity

- Treatment of non-union, femoral neck fracture, and trochanteric fractures of the proximal femur with head involvement, unmanageable by other techniques.

- Revision of previously failed total hip arthroplasty.

- Dislocation risks.

The G7 Dual Mobility Acetabular System are singleuse implants, intended for uncemented applications.

CONTRAINDICATIONS

Absolute contraindications include: infection, sepsis, and osteomyelitis.

Relative contraindications include: 1) uncooperative patient or patient with neurologic disorders who are incapable of following directions, 2) osteoporosis, 3) metabolic disorders which may impair bone formation, 4) osteomalacia, 5) distant foci of infections which may spread to the implant site, 6) rapid joint destruction, marked bone loss or bone resorption apparent on roentgenogram, and 7) vascular insufficiency, muscular atrophy, or neuromuscular disease.

For full prescribing information, including Indications for Use, Contraindications, Warnings, Precautions and Possible Adverse Effects, see the package insert and Patient Risk Information under the “Patient” tab on biomet.com.