Alliance® X-Series Implant Technology

FEATURES & BENEFITS OF ALLIANCE® X-SERIES IMPLANTS:

• Simple Standard Instrument Sets:

Incorporating one common set of instruments, the Exact™ hip instruments are used to implant all Alliance® X-Series components. This feature provides the surgeon with maximum flexibility and simplifies procedures for the OR staff while reducing instrument inventory for the hospital.

• Alliance® X-Series Surface Coatings:

The X-Series implants offer a variety of surface finishes that promote fixation. Biomet’s porous plasma sprayed components have shown significantly lower rates of osteolysis than other circumferentially-coated components.

Proximal circumferential non-interconnected plasma spray works in conjunction with the implant design for optimal bone ingrowth. A roughened Interlok® finish provides the medium for bone ongrowth and the smooth or polished portions of the stem is consistent with proximal fixation.

• Net-Forgings:

Net-forging technology provides a more precise fit for the implant. The “human variability” associated with hand polishing is reduced, allowing superior reproduction of the compound angles on the finished implant. In addition, net-forgings adhere to the industry’s most exacting dimension tolerances, which provide a more consistent broach-to-implant fit.

TRADITION AND TECHNOLOGY

The Alliance® family of femoral components uses net-shape forgings and advanced manufacturing technology to optimize the consistency of multiple geometries and configurations. The foundation for the X-Series of implants are the excellent long-term clinical results of proximal-to-distal tapered stem geometries. The combined technology and geometries have proven to meet the needs of both the patient and the surgeon for successful cementless hip reconstruction.

Meticulous design and superior materials, combined with improved manufacturing techniques, have allowed for advanced concepts in femoral components and instrumentation. Net-shape forging technology results in a consistent and reproducible surgical technique.

This advanced technology provides a more precise envelope for the implant, which has greatly reduced the “human variability” associated with previous manufacturing methods. This technology has been integral in the development of superior standards of performance. The X-Series implants maximize the effectiveness of net-forging technology while maintaining the specific features that surgeons prefer.

The X-Series implants are manufactured using three-dimensional CAD-CAM techniques. Computer-aided design (CAD) and computer-aided manufacturing (CAM) have revolutionized the manufacturing process. 3D CAD-CAM engineering technology is superior over previous 2D CAD-CAM designs in that 2D technology allowed for two-dimensional drawings to be designed in limited planes. Due to this limited technology, there was a possibility for variability in the fi nal design. New, innovative processes permit creation of the actual implant, while eliminating manufacturing steps. Recent developments in three-dimensional solid modeling technology allow for designs to be viewed and manipulated from all angles. This technology provides accurate interpretation of compound planes and complex implant geometries, leading to the precise and consistent development of femoral components and related instrumentation.

TITANIUM PLASMA SPRAY

Plasma spray is a three-dimensional distribution of randomly dispersed titanium particles. Biomet’s proprietary plasma spray application is unique in that only the titanium alloy powder used to create the coating is heated, not the implant’s substrate. Plasma spray porous coating is applied to the substrate of the implant at a low temperature, which preserves up to 90% of the mechanical strength of the implant. Randomly shaped particles are flattened upon impact with the substrate. An arbitrary distribution of pore size between 100 and 1,000 microns is generated, providing a larger contact area between the particles and the substrate.

The resulting surface is rough in contrast to the smooth surfaces of a beaded implant. Implant stability, interface strength and contact to the bony surface area are maximized by the irregular surface. This feature allows the implant to scrape bone into the pores during implantation, providing solid initial fixation. In addition, the random particle dimensions result in a varied pore size distribution. Smaller pores are important for initial fixation because they quickly fill in with bone, promoting early osseointegration. Larger pores require a longer time to fill in and provide for long-term fixation with continued macro bone in-growth. Bony in-growth is important for mechanical interlocking and maximum load transfer. Studies show that “rough titanium has been found to have a good propensity for encouraging adhesion of osteoblasts.”

Circumferentially coating the femoral component with plasma spray creates a barrier to particulate debris (metallic, polyethylene or PMMA), which can trigger a macrophage response that can initiate osteolysis. Tanzer, et al., have reported that sealing the endosteum from the pumping of debris may be the most important factor in preventing osteolysis in total hip patients. The lack of longitudinal pore interconnectivity creates a seal from this particulate debris migration, which may help to reduce osteolysis and improve long-term fixation. While other femoral components have circumferential porous coating, it is not Biomet’s clinically proven non-interconnected plasma spray.

LATERAL OFFSET RESTORATION

In total hip reconstruction, the most effective and easily manipulated mechanical variable available to the surgeon to optimize the biomechanics of the hip is the offset of the prosthesis. A lateral offset option allows the surgeon to enhance joint stability and restore normal hip function. If the potential offset deficiency is not identified or treated, it could lead to joint instability, limp, and increased joint reaction forces. The advantage, intra operatively, is that it allows for adjustment of offset and soft tissue tension without changing the neck resection level or the length of the leg.

The X-Series implants employ two methods of achieving optimal offset restoration. For the Integral® femoral stems, lateralization is achieved by shifting the neck geometry of the implant medially 6mm while maintaining a constant neck shaft angle and slightly increasing the length of the taper. The Bi-Metric® X-Series addresses lateral offset by lowering the neck angle, slightly increasing the length of the trunion, and shifting the neck geometry medially in proportion to the stem size.

Bi-metric® Porous Primary Hip X-Series system

BI-METRIC® HIP SYSTEM

Since its introduction in 1984, the Bi-Metric® Hip System continues to provide a high degree of versatility and unsurpassed clinical performance. Developed by a team of orthopedic surgeons and engineers, the Bi-Metric® hip stem’s major design concept of a 3° bi-planar taper is incorporated throughout nearly every Biomet hip system. The bi-planar taper and distinct lateral-to-medial taper provide physiologic proximal load transfer and preserve distal cortical bone, signifi cantly reducing the likelihood of proximal resorption.

KEY DESIGN FEATURES:

LATERAL OFFSET RESTORATION:

The collarless Bi-Metric® Primary Porous Hip is available in a standard and lateralized offset. In-depth studieshave concluded that femurs with greater horizontaloffset often have a more varus neck shaft angle. As the stem size increases, the required offset also increases. The Bi-Metric® lateralized component’s design is based on this philosophy. The offset is achieved by decreasing the neck shaft angle, medially shifting the trunion and increasing the neck length, while not affecting leg length.

All of these key features work in unison to promote gradual off-loading of stresses from the femoral component throughout the entire femur.

Alliance® X-Series/ Exact™ Instrumentation Experience

INSTRUMENTATION

The Exact™ Hip Instrumentation was designed for improved effi ciency in the OR. The system includes precision instrument designs that promote accuracy, provide reproducible results, and complement Biomet’s clinically proven femoral components. Alliance® femoral components can be implanted using only three trays: the General I Insertion case and the Alliance® system-specific Reamer and Broach cases. The broach cases can accommodate up to 12 different neck trunions to support any Alliance® implant. Recognizable color-coding identifies the instrumentation specific to the selected femoral component.

KEY COMPONENTS OF THE EXACT™ INSTRUMENTATION ARE:

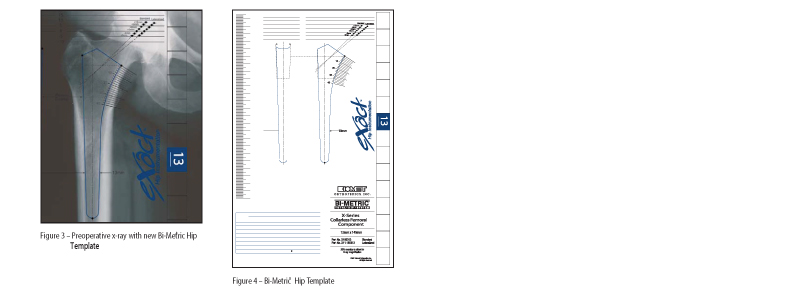

X-RAY TEMPLATES: PREOPERATIVE PLANNING

The new Exact™ Template system offers a precise technique for implant sizing and preoperative evaluation of anatomic offset. Vertical and medial scales correspond to the resection guide to aid in leg length restoration. The templates are designed to match the color-coded instrument case for ease of identifi cation and offer a table for quick offset references.

Bi-Metric® Primary Hip X-Series Surgical Technique

FEMORAL HEAD RESECTION

Using the Exact™ templates, determine the height of the femoral neck resection above the lesser trochanter and the height of the tip of the greater trochanter relative to the shoulder of the femoral component. The Alliance® femoral neck resection guide references these measurements intraoperatively. Position the femoral neck resection guide parallel to the longitudinal axis of the femoral shaft. Confirm the height of the femoral neck resection above the lesser trochanter using the scale on the medial aspect of the resection guide relative to the preoperative templated X-ray. The vertical scale referenced to the greater trochanter is an additional conformation of the resection level. Resect the femoral neck at this level to re-create the appropriate femoral neck length and offset.

ACCESSING FEMORAL CANAL

The Exact™ Offset Chisel is used to access the piriformis fossa and to clear a channel to accept the tapered reamers. The design provides for adequate visualization for a lateral pathway to avoid varus positioning. A Starter Reamer on a T-handle may be used to identify the femoral canal.

REAMING FEMORAL CANAL

The Alliance® Exact™ Reamers are proportionally sized tapered reamers with blunt tips that are used to progressively enlarge the intramedullary canal to the size estimated by preoperative templating. In determining reamer depth, the proximal tip of the greater trochanter is used as a landmark to reference the femoral head center in conjunction with the reference bands on the reamer shaft, femoral resection guide, and the Exact™ Templates. Bands along the reamer shank reference the vertical scale on the templates and the resection guide, which correspond to the center of the femoral head. For example, if the templated vertical scale is a 10, bury the reamer until the 10mm mark on the reamer corresponds to the top of the greater trochanter for accurate femoral depth.

Begin with a canal reamer that is 3–4mm smaller than the templated femoral component. Sequentially ream the femoral canal until cortical “chatter” is encountered. It is important to stay lateral and posterior with the femoral reamers to ensure that the canal is being prepared in neutral alignment with the femoral axis.

BROACHING PROXIMAL FEMUR

Begin the broaching process with a broach at least 2–3mm smaller than the largest reamer used. Attach the broach handle to the broach by pulling back on the trigger and locking it into place. It is important that the broach is oriented to produce the desired femoral anteversion. Sequentially increase the size of the broach until the templated size is reached or until the broach engages the medial cortex and can not be placed deeper. With the properly sized broach in place, the calcar can be planed fl ush by using the retractable calcar planer if necessary. The calcar planer is specially designed to reach the short broach post and prevent metal-to-metal wear of the post.

TRIAL REDUCTION

To perform the trial reduction with the final broach still in place, attach the appropriate Exact™ Alliance® magnetic neck trunion over the extended broach post. The gold trunion indicates standard offset, while the black trunion represents lateralized offset. The Exact™ magnetic trunions are sized to correspond to the appropriate broach size with the stem size clearly marked on top of the trunion. Select the trial femoral head of desired diameter and neck length (If using a collared trial, the collar should rest on the proximal femoral neck). Reduce the hip to ensure that proper leg length and joint stability have been achieved. In performing the trial range of motion, ensure the absence of impingement of the femoral neck on the rim of the acetabular component or acetabular liner.

INSERTING POROUS IMPLANT

The stem corresponding to the size of the final broach is threaded onto the femoral stem inserter. The femoral inserter handle assists in controlling rotation of the implant and allows the implant to be placed into the femoral envelope with the proper amount of anteversion. The stem should slide distally into the canal without much resistance until the stem is 5–10mm proximal to the calcar.

As resistance is met, gently tap the inserter until the implant is seated. If desired, another trial reduction can be accomplished prior to impacting the modular head onto the stem. Provisional heads in seven neck lengths allow an additional trial reduction using the actual implant to ensure proper leg length and stability. After fully seating the femoral component, the appropriate modular head is impacted onto the clean, dry taper.